Epiroc Pit Viper

Product Overview

The HMWS team were commissioned to undertake a complete re-design of the electrical architecture and associated harness and cable assemblies for a fleet of Epiroc Pit Viper 271 Rotary Blasthole Drills. The design considered the functional requirements of serviceability and reliability. With the rigs often operating in remote locations, the need for ease of serviceability, fault finding, and reliability is paramount.

The HMWS plug and play design included:

• Electrical enclosures that protect the electrical components, and eliminates all cable splices.

• Overmolded LED connectors for fast fault finding and quick and easy replacement.

• Connector port identification for ease of serviceability, fault finding and cross-referencing to the schematics and part number identification for ease of reordering.

Enclosures

Engine Enclosure

THE ENGINE ENCLOSURE HAS A NUMBER OF BENEFITS THAT INCLUDE:

• A momentary starter isolation switch that allows for function testing of each starter motor.

• Resettable circuit breakers that protect all systems powered by the engine.

• The enclosure acts as the break out hub for engine specific controls and sensor circuits, offering additional protection from the harsh operating environments.

• Engine diagnostic connector for maintenance crew laptops.

• LED internal lighting.

Non Cab Side Enclosure

• Consolidating and protecting resettable circuit breakers from harsh operating environments.

Enclosures

A-Frame Enclosure

THE A-FRAME ENCLOSURE HAS A NUMBER OF BENEFITS THAT INCLUDE:

• Incorporated Bus Receptacles replacing wire splices which improves serviceability and ease of adding additional circuits if required.

• Consolidates all hydraulic solenoid cables into one enclosure for improved serviceability.

Isolation Enclosure

Consolidated all lock-out isolation points into one enclosure providing easy access and serviceability for maintenance crews.

Air Conditioning Enclosure

Consolidating and protecting resettable circuit breakers from harsh operating environments.

Overmolded Cables

OVERMOLDED POINT TO POINT CABLES SIMPLIFY THE PLUG AND PLAY DESIGN, BENEFITS INCLUDE:

• 2, 4, 8 and 12 way strain relief.

• LED lighting is incorporated into the over-moulded connector for ease of fault-finding.

• Protects against water ingress and oxidisation.

• Use a Hi-Flex cable with a larger wire gauge and tinned copper braided protection increasing mechanical integrity.

• Increased wear and tear resistance by adding a low adhesive and flexible polyurethane thermoplastic (PUR) outer sheath with a fixed installation temperature range from -40C to +80C. The PUR outer sheath offers additional protection which is halogen-free, resistant to most oils and greases, flame retardant and UV rated.

Cable Trays

Designed and manufactured cable trays for the mast and chassis to protect and secure the overmoulded and trunk cables.

• Easy install and access for maintenance crews.

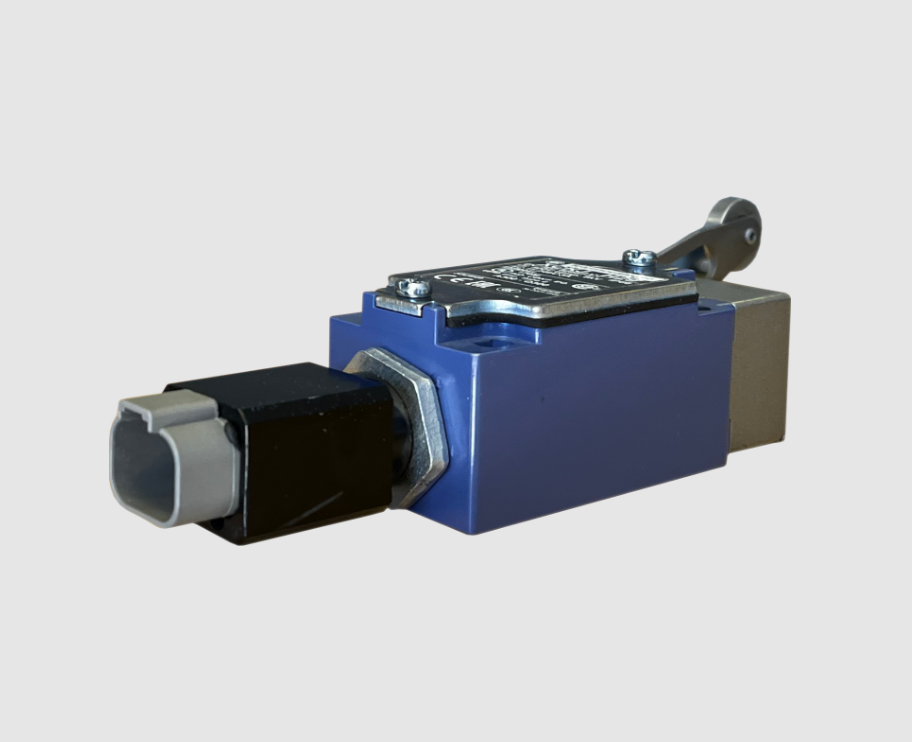

Limit Switches

Designed and manufactured a Deutsch adapter to accommodate a plug and play approach for all limit switches.

Operators Cabin Dashboard

• Redesigned and manufactured the operators' dashboard to facilitate the plug and play approach.

• Converted RCS to a non-RCS cabin to optimise serviceability in remote areas.

• Weld in Bulkheads were incorporated into operator cab walls to maintain the plug and play approach.

• Engine diagnostic connector for maintenance crew laptops.

Trunk Cable and Bulk Heads

Trunk Cable

• Eliminated all harness joins by designing and manufacturing a simple trunk harness that connects all relevant electrical enclosures.

Bulk Head Connection Panel

• Eliminates cable passing through operator cab walls eliminating rub points and dust and water ingress.

• Improves electrical harness life and reliability.

• Quick and easy cable replacement with connector labelling for fast identification.

• Future-proofing by adding additional cable ports for future ancillary options/additions.

Aftermarket Support

• All parts and components assigned part numbers for ease of reordering.

• Schematic issued for servicing and fault finding.

• Recommended spare parts list generated to highlight critical parts.

• HMWS held stock to support breakdowns and maintenance activities.